- Home /

- CO COMPOUNDS /

- CO Cutting /

- CO Fluid /

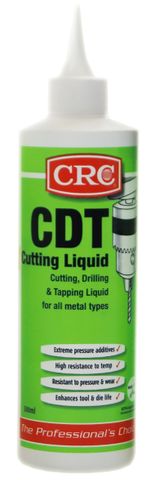

- CRC CDT CUTTING LIQUID 500ml BOTTLE

Our Products

- AB ABRASIVES

- AU AUTOMOTIVE

- CO COMPOUNDS

- CU CUTTING TOOLS

-

FA FASTENERS

- FA Cap 10.9

- FA Cap 12.9

- FA Cap 316

- FA Coach Bolt

- FA Flange Non Serrated Bolt

- FA Hex 10.9

- FA Hex 316

- FA Hex 4.6

- FA Hex 8.8

- FA Hex G8

- FA Masonry

- FA Nut 316

- FA Nut Castle

- FA Nut Class 6

- FA Nut Flange Serrated

- FA Nut G5

- FA Nut G8

- FA Screws

- FA Staples

- FA Threaded Rod

- FA Threaded Rod 316

- FA Threaded Rod 4.6

- FA Washers

- FO FOOD GRADE

- GE GENERAL

- HA HARDWARE

- HT HAND TOOLS

- IN INDUSTRIAL HOSE & FITTINGS

- LUB LUBRICATION

- PN PNEUMATICS

- PT POWER TOOLS & PARTS

- SA SAFETY

- TE TECHNICAL DATA

- TR TRANSMISSION

- TS TOOL STORAGE

- WE WELDING

- WI WIRE BRUSHES & WHEELS

- WO WORKSHOP EQUIPMENT

CRC CDT CUTTING LIQUID 500ml BOTTLE

Description

CRC CDT Cutting compounds are superior neat cutting, drilling tapping, and reaming lubricants, formulated for hand and machine cutting on all types of metal. They significantly reduce friction and wear, increase cutting speeds, protect and extend tool life, and ensure consistent, high quality surface finish.

CRC CDT Cutting compounds contain extreme pressure additives and create a strong film with increased 'cling' for use on vertical surfaces, allowing for work at any angle.

CRC CDT Cutting compounds leave an anti-corrosive residue and are safe to use on soft metals such as brass, copper, and aluminium.

Available as:

CDT Cutting Oil - Convenient aerosol ideal for mobile engineers and mechanics working off-site.

CDT Cutting Liquid - Heavy duty viscous fluid, in a convenient squeeze bottle. May also be used as an extreme pressure additive booster for standard neat cutting oils, for difficult cutting operations such as broaching and gear manufacturing on the toughest metals.

CDT Metal Cutting Paste - Heavy duty viscous paste, can be applied by brush or by dipping tool into the compound.

Features & Benefits

Contains high performance, extreme pressure additives

Provides very high resistance to temperature, pressure and wear

Enhances tool, mandrel and die life - Reduces tooling and production costs

Increases cutting performance

Cuts downtime

Provides a homogenous and tenacious lubricating film

Consistent, high quality surface finish

Flexibility - Suitable for use on a wide range of applications and materials

Freedom from scoring due to high welding resistance

Reduction of scrap

Suitable for hand and machine cutting

MPI Approved C12 (all animal product except dairy)

400ml Aerosol Includes PermastrawÖ Dual-Action Spray System - One piece actuator with two-way spray that ensures that straw stays in place.

Uses

Metal cutting operations

Cutting

Drilling

Tapping

Reaming

General workshop applications

Also ideal for tube drawing and extruding, cold forming and deep drawing of difficult steels such as stainless steel, high nickel alloys, chrome alloys, nimonics and aluminium.